SeaShield™ offers the most comprehensive range of control and corrosion prevention systems for coastal fuels and marine structures. The wide range includes protection of marine structures; sealed walls; wooden, concrete and steel poles with a round, square or hexagonal shape.

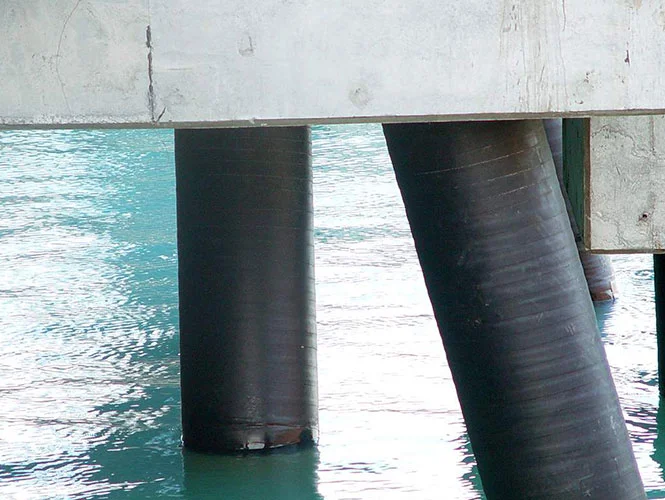

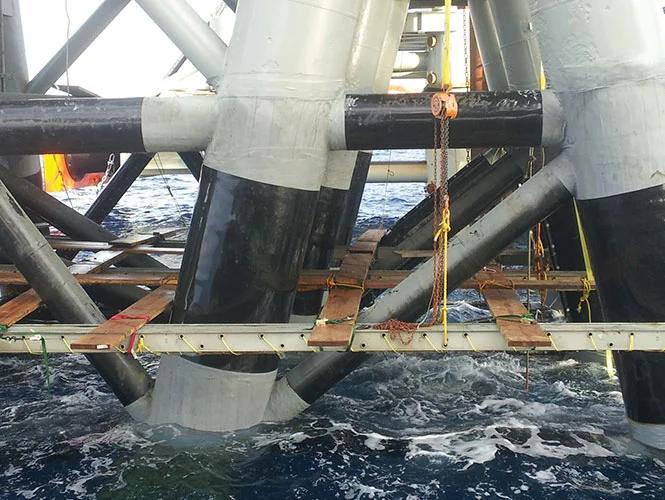

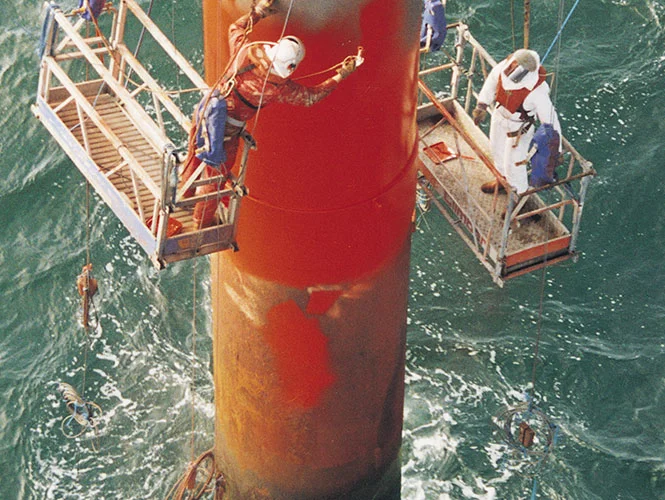

This extremely popular and time-tested system, which can be used both above and underwater, provides robust protection for marine structures that are exposed to corrosive conditions occurring in offshore zones, in between tidal and submarine environments. The durable, multi-layer corrosion protection system with the durable HDPE outer cover is applicable in the following areas:

Optional addition to the SeaShield 2000FD™ system, the patented inspection port allows you to quickly inspect the ground without having to dismantle the entire system.

Patented inspection ports are made of high density polyethylene and other materials that are suitable for marine applications. HDPE is specially developed to contain a minimum of 2% saline, which ensures excellent resistance to UV weather conditions.

Lightweight system for cylindrical steel, concrete or wooden fire protection.

The system consists of a Prempaste S105™ paste layer followed by a SeaShield™ Marine Piling layer. The system is supplemented by the addition of the last layer of SeaShield Bitumen Outerwrap 80™, which consists of a fabric of synthetic fibres impregnated and coated with a polymer-modified bitumen mixture, laminated on a hard PVC substrate. The mass layer is protected by a plastic film cover, which is removed during application. The combination of the PVC substrate and the polymer bitumen mass reinforced with fabric makes it resistant to damage by sharp objects (np. uderzenia).

Robust tape system to protect uneven steel, wooden or concrete fires.

The system consists of the Prempaste S105™ layer followed by the SeaShield™ Marine Piling layer. The SeaShield Glass Outerwrap 70™ layer is applied to complement the system. SeaShield Glass Outerwrap 70 is a glass fiber fabric impregnated with water-activated resin, used as a protective coating that provides exceptional mechanical and impact strength.

A single-layer system in liquid to protect steel fuels and structures in aggressive marine environment.

A single-layer polyester coating that offers the traditional properties of glass cylinder reinforced systems with additional advantages. This improved material can be applied by airless spraying method to obtain a dry coating thickness of 750-1000 microns in one layer. The system is designed to protect all steel structures in coastal and marine conditions where the phenomenon of abrasion and erosion is a significant problem, e.g. in the shoreline zone. Operation temperature: – 50°C to 65°C.

For documentation, please fill in the form or contact us.