synthetic casing filler

Product description:

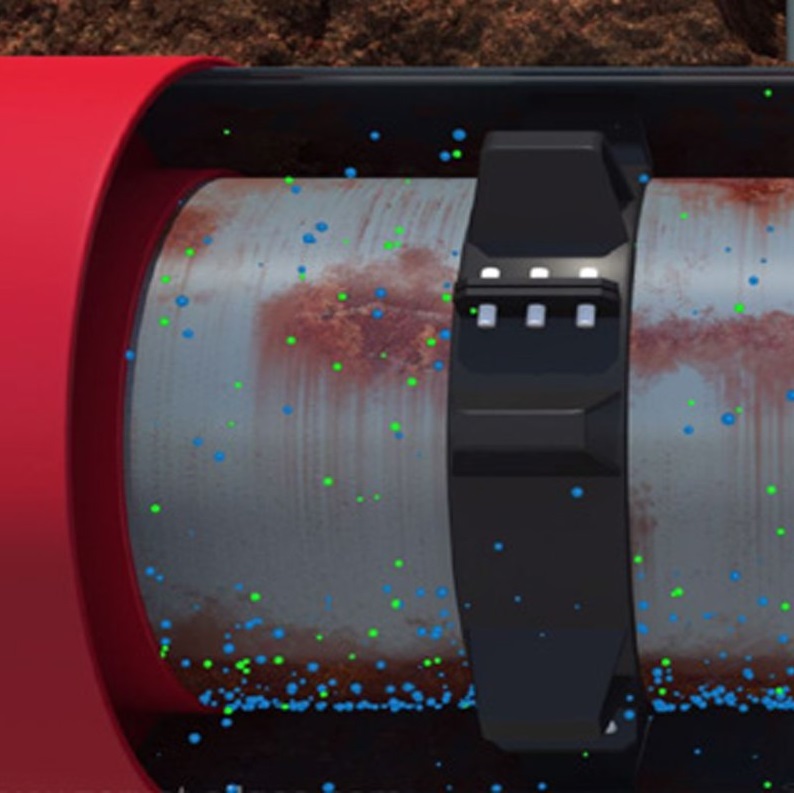

SFP Casing Filler FS™ is the most effective solution to prevent corrosion of steel pipelines in housing. Water and oxygen, which are normally present in an unfilled cover pipe, cause corrosion of the operating steel pipeline, as well as internal corrosions of the steel cover tube. By filling the ring between the cover pipe and the product pipe with the SFP Casing Filler FS™, water and oxygen are drained away, eliminating corrosion.

For documentation, please fill in the form or contact us.