Steelcoat™ systems are designed to protect poorly secured or new surface steel structures in highly aggressive environments. Compliant with the highest standards and environmentally friendly systems offer a long-term, cost-effective corrosion prevention solution.

A hand-mounted surface-tolerant system designed to provide a long-lasting protective coating for the sensitive base of the pillars in corrosive environments.

The system consists of the PremtapeTM Hi-Tack Primer base for the coating of the purified substrate and the premtape TM LD Mastic preparation for filling empty spaces and creating any angles required to obtain a smooth profile. The PremtapeTM Hi-Tack layer is then applied to the area, followed by the Premier D5TM Scrim layer. A PremierTM Basecoat layer is applied to supplement the protection system. Optional acrylic surface coating is available.

The Steelcoat 100/400™ connected system is now widely recommended for demanding applications, as it combines all the advantages of the two SteelCoat™ systems. The combined system exists in two variants A and B.

Combining two Premier Steelcoat™ systems to provide additional protection in difficult locations such as corrosive and rusted steel pipes/constructions and wet steel tubes/structures

The Steelcoat 100/400™ connected system is now widely recommended for demanding applications, as it combines all the advantages of the two SteelCoat™ systems. The combined system exists in two variants A and B.

For larger corrosive rods, rusted pipelines and steel structures. In the case of pipelines, the Steelcoat 100/400(A) consists of a Premtape™ Hi-Tack Primer base, followed by a double wrapping (55% of the tab) of the Premtape™ Hi-Tack. The outer layer Premier Ultraseal RT™ is applied with a 25% bet before painting. For steel structures, the Steelcoat 100/400(A) system is applied as above, but with only one layer (label 25%), followed by the Premier Ultraseal RT with a label 25% before painting. After applying Premier Ultraseal RT to the fabric substrate, it is covered with two layers of Premier™ Acrylic Topcoat surface coating.

For wet pipeline surfaces. As above “To pipelines” with Prempaste S105™ replacing Premtape™ Hi-Tack Primer:

The Steelcoat 300™ system consists of a gray vaseline tape (Steelcoat™ ColourTape), which is ideal for small to medium-sized pipes. No substrate is needed, and the manual application or wrapper is fast and easy.

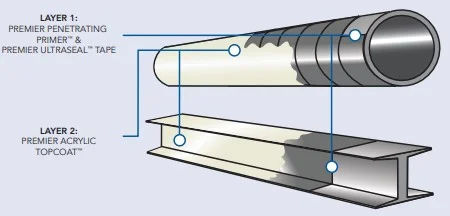

The Steelcoat 400™ system consists of a Deep Penetrating Primer (Premier™), an easy-to-apply layer onto a fabric base (Premiere Ultraseal™) and a surface layer (Premier™ Acrylic Surface Coating). The end surface can be reinforced with a selected reinforcement mesh (Premier D5™ or Premier D10™ Scrim) for sections of steel structures or pipelines that require additional impact resistance.

After grounding, Prempaste™ LD Mastic is first used to seal and profile corners, empty spaces, collars or connectors before applying Premier Ultraseal and the selected surface layer. Ideal for deep corrosion or rusted steel structures.

Two-component polyester resin coating reinforced with glass tiles to protect structural steel in aggressive environments such as bridges, slugs or marine applications

The Steelcoat 1000™ system consists of a two-component polyester-glass coating with reinforced rigspray (Premier Rigspray™), which provides exceptional corrosion and abrasion resistance. For protection of structural steel in aggressive environments such as bridges, muzzle gates or in marine applications and where abrasion and erosion occur are common at temperatures up to 65°C.

The durable coating is applied by airless spraying method and can reach a dry layer thickness of 1 mm or 1000 microns in one application operation. Good mechanical resistance of the coating is achieved within 3 hours at a temperature of 25°C. To extend the lifetime, two layers of 750 microns per layer are applied to increase the total thickness to an average of 1500 micrones.

For documentation, please fill in the form or contact us.